Cruise Lines Advance Net-Zero Goals With Tri-Fuel Ships and AI Solutions

Alongside investing in new ship designs and alternative fuels, cruise lines are integrating AI, port infrastructure, and waste innovations to help reach industry-wide climate targets.

The cruise industry is rapidly embracing technological advancements and sustainable practices in pursuit of its net-zero 2050 emissions goal. From groundbreaking fuel-flexible systems to innovative waste management and energy efficiency solutions, cruise lines and shipyards are transforming operations to address environmental concerns while maintaining high-quality passenger experiences.

Fuel Flexibility Leads Sustainable Innovations

A notable milestone in fuel flexibility is the upcoming debut of Celebrity Cruises’ 3,260-passenger Celebrity Xcel in November. As the first purpose-built tri-fuel cruise ship, Celebrity Xcel will operate on liquefied natural gas (LNG), methanol, and conventional marine fuels, with future options to adopt bioLNG and green methanol as supply scales. A Royal Caribbean Group spokesperson highlighted the line’s intent to closely monitor and refine this new technology for efficiency gains.

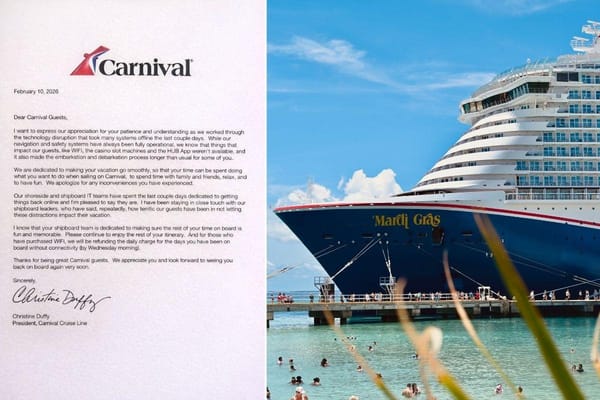

Fuel trials are becoming widespread across the industry as cruise lines assess viable paths toward reduced lifecycle emissions. Carnival Corporation, Royal Caribbean Group, Norwegian Cruise Line Holdings, and MSC Group are piloting biofuels, including those derived from used cooking oil and non-food biomass. Successful tests have been conducted on ships such as AIDAprima, Holland America Line's Volendam and Rotterdam, and Carnival's Carnival Magic, though limited supply remains a challenge.

Technological Advances to Cut Immediate Emissions

Shore Power Reduces Port Emissions

Onshore Power Supply (OPS) capability, which enables ships to connect to local electrical grids while docked, has proven effective in reducing berth emissions by up to 98%. Currently, 166 ships (58% of Cruise Lines International Association's, CLIA, fleet) are equipped with OPS, a figure expected to climb to 273 ships (85%) by 2036. Ports worldwide are expanding infrastructure to support this environmentally friendly solution.

Energy-Efficiency Systems and AI

Several initiatives aimed at minimizing energy use and emissions are becoming standard across the fleet. Air lubrication systems, utilized by 33 ships from major brands including Carnival, Norwegian, and Royal Caribbean, create a cushion of microscopic air bubbles under the hull to reduce drag and fuel consumption.

Waste heat recovery systems are reclaiming surplus heat from engines to provide energy for onboard heating needs. Additionally, AI platforms like Royal Caribbean's Marine Insights and Analytics tool are optimizing fleetwide efficiency, identifying specific opportunities to lower fuel consumption.

Waste Management: Driving Cleaner Operations

Biodigestors and Waste-to-Energy Systems

The cruise industry is increasingly turning to cutting-edge waste management systems to minimize environmental impact. Biodigestors, now installed on 128 ships, break down organic food waste into a harmless byproduct that can be safely disposed of. New ships from Royal Caribbean and Silversea also carry waste-to-energy gasification systems, which convert solid waste into usable onboard power, reducing landfill contributions.

AI-driven tools, such as Orbisk’s image recognition software, are actively helping Carnival Corporation monitor food waste patterns. These solutions allow kitchens to align meal production with consumption while robots remove plastic and glass contaminants from food waste for safer processing.

Methanol and Modular Shipbuilding

At Turkey’s Tersan Shipyard, methanol is emerging as a critical focus in shipbuilding due to its lower carbon footprint, safety in handling, and future net-zero potential. Marketing Communications Executive Elif Sahin noted growing demand for hybrid propulsion systems and alternative fuels such as ammonia, wind power, and biofuel. The shipyard specializes in modular designs that enable upgrades over time, leveraging smart energy monitoring, shore power compatibility, and waste recovery systems.

Tersan’s projects include methanol-fueled chemical tankers for Tune Chemical Tankers and dual-fuel service operation vessels for Acta Marine. Additionally, LNG and battery-hybrid vessels, such as Havila Kystruten's coastal ships, have been delivered to enable some zero-emission operations.

“Each vessel is built to spec and optimized for long-term performance,” said Sahin, referring to Tersan’s dual design approach, which integrates external collaboration alongside a robust in-house design team equipped with advanced digital tools.

Behind-the-Scenes Experiences for Passengers

While many sustainability innovations operate behind the scenes, cruise lines are engaging passengers in learning opportunities onboard. Guided environmental tours offered by lines such as Ponant often sell out quickly, providing access to areas like wastewater treatment systems and engine rooms. Researchers and scientists onboard conduct educational sessions and experiments on select expeditions, such as those organized in partnership with the Woods Hole Oceanographic Institution.

Such initiatives not only inform guests about sustainable practices but also demonstrate the cruise industry’s commitment to improving its environmental performance.

Frequently Asked Questions (FAQs)

When does Celebrity Xcel debut, and what fuels can it use?

Celebrity Xcel is scheduled to debut in November, operating as a tri-fuel ship capable of running on LNG, methanol, and conventional marine fuels. Its design also accommodates emerging options like bioLNG and green methanol.

What is shore power and how widespread is it in cruising?

Shore power allows ships to connect to local electrical grids and turn off engines in port, reducing emissions by up to 98%. About 58% of CLIA’s fleet is OPS-capable today, with the number expected to rise to 85% by 2036.

Are cruise lines already using biofuels?

Yes, several cruise lines, including Carnival Corporation and Holland America Line, are piloting biofuels derived from used cooking oil and other renewable sources. Multiple ships have successfully used biofuels as supplemental energy during voyages.

How do air lubrication systems save fuel?

Air lubrication systems release microscopic air bubbles under the hull, reducing friction between the ship and seawater. Lower drag leads directly to reduced fuel burn and emissions.

What onboard systems are cutting waste and energy use?

Waste-to-energy gasification systems and biodigestors minimize landfill contributions, while waste heat recovery systems maximize energy efficiency. Artificial intelligence also improves fuel consumption and waste management onboard ships.