Carnival Schedules 600+ Drydock Days in 2026 for Efficiency Retrofits

Carnival is turning routine yard time into a proving ground for repeatable fuel-saving retrofits, reflecting how cruise lines are chasing efficiency as rules tighten.

Carnival Corporation is preparing for more than 600 drydock days across its eight cruise brands in 2026, Chief Financial Officer David Bernstein said during the company’s year-end and fourth-quarter earnings call in December.

The heavy shipyard calendar is also central to Carnival’s energy-efficiency and emissions-reduction push, with corporate marine technology teams using planned dockings to test, validate, and scale technical upgrades that can be repeated across the fleet.

Turning routine drydocks into a fleetwide efficiency window

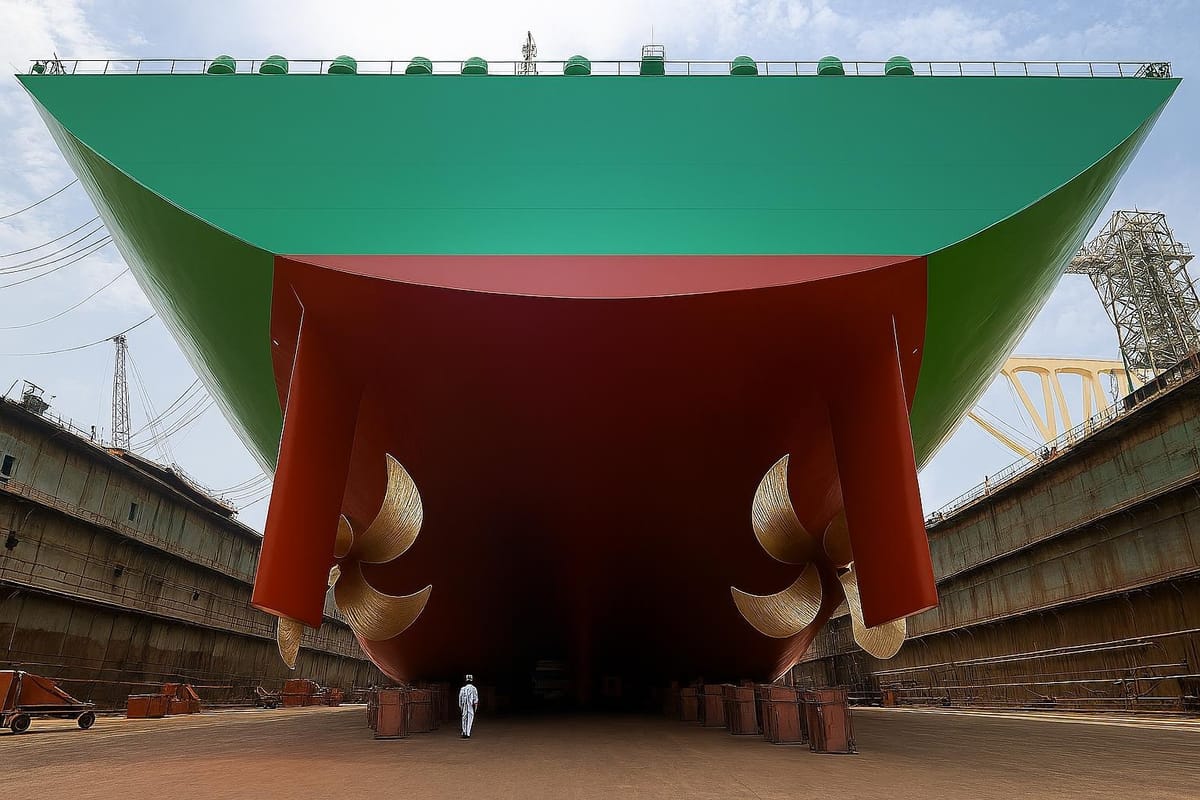

Chris Millman, vice president of corporate marine technology at Carnival Corporation, said the company views shipyard periods as a chance to tackle technical work that is difficult or impossible to do while a vessel is operating. “We see drydocks as opportunities,” Millman told Cruise Industry News, describing a mix of projects that can range from new equipment installations to hull blasting, coatings, and thruster-related modifications aimed at improving hydrodynamics.

Carnival’s individual brands manage their own drydock periods and often balance maintenance needs with guest-facing projects, while the corporation provides support for larger technical initiatives that can be scaled across multiple ships, Millman said.

Air lubrication systems move from trials to broader rollout

A key corporate-led program involves air lubrication systems (ALS), which reduce friction between a ship’s hull and the water by creating a layer of air bubbles along the underwater surface, improving hydrodynamic performance and lowering fuel consumption.

Millman said Carnival’s ALS effort began with two early installations, one on a newbuild and another as a retrofit on an existing vessel, followed by about two years of operational data collection to evaluate real-world performance. “We needed to get a real feel for how it was working... It came out positive, and that is why we went forward with a corporate-wide program,” he said.

As the program expands, Millman said additional systems are in the pipeline. “We have another six of those on order,” he said, adding that the evaluation process looked beyond headline fuel-savings claims to how the equipment interacted with other ship systems.

Underwater hull focus includes coatings and thruster-grid work

Alongside ALS, Millman said Carnival has increased its attention on the underwater hull and drag reduction, including advanced blasting and painting techniques and the application of antifouling coatings during drydock periods. “We’re paying special attention to the underwater hull,” he said.

He also cited what he described as a significant program involving thruster grids, as well as broader efforts tied to hull hydrodynamics and propulsion-adjacent improvements intended to enhance overall efficiency.

Waste heat recovery expands with an absorption chiller retrofit

Carnival is also pursuing efficiency gains through onboard energy systems, including HVAC-related work and a service-power-pack approach intended to generate recommended modifications that can be applied during drydock to improve performance, Millman said.

Waste heat utilization is another area receiving increased attention, including technologies that convert heat that would otherwise be lost into useful cooling. “We’re fresh off a retrofit of an absorption chiller on a Carnival Cruise Line ship,” Millman said. He noted the technology had previously been used on a newbuild, but added, “We’ve had them on a newbuild, but this is the first retrofit of this system,” describing the installation as a way to use waste heat to produce chilled water and reduce overall energy consumption.

Millman said the company continues to look for additional ways to capture more value from waste heat onboard. “How do we best capture and utilize waste heat?” he said, calling it an area with significant remaining opportunity.

Digital twins and longer planning horizons for ship-specific upgrades

As Carnival pushes beyond initial rounds of fleetwide upgrades, Millman said the next phase becomes more tailored to individual vessels. “We’re pushing forward with our next iteration of improvements,” he said, pointing to more ship-specific service-power packages guided by modeling that helps identify where investment delivers the best returns.

To assess changes before committing to shipyard work, Carnival is using digital twins, virtual replicas of ships that allow teams to test and refine energy-saving measures ahead of installation. Millman also outlined the lead times the company uses for yard planning. “We are in a typical drydock cycle, looking five years in advance,” he said, adding that larger efforts are generally planned two to three years out, while smaller items are often organized about a year ahead, supported by prototype trials and evaluation work.

He described the progression as incremental, noting, “Once you’ve done that first level of work, the next level is a bit harder,” as the remaining gains require increasingly targeted analysis and engineering.

2026 drydock calendar: AIDA Evolution and multiple Carnival Cruise Line yard stays

Bernstein said 2026 will be an especially busy year in shipyards across Carnival’s portfolio, with more than 600 total drydock days expected across eight brands. He also said spending tied to drydocks is expected to remain comparable to prior years.

Among the largest scheduled projects are two nearly 50-day dockings for AIDA Cruises ships AIDAbella and AIDAmar under the AIDA Evolution upgrade program. AIDAbella is slated to enter drydock starting in January, while AIDAmar is scheduled for a November transformation.

Carnival Corporation President and CEO Josh Weinstein said the AIDA Evolution concept will not remain limited to AIDA, adding that it is “soon poised to expand” to several other brands in the company’s portfolio.

The 2026 plan also includes extended yard stays for multiple Carnival Cruise Line ships:

- Carnival Elation is scheduled for January.

- Carnival Pride is scheduled for March.

- Carnival Magic is scheduled for April.

- Carnival Freedom is scheduled for September.

- Carnival Luminosa is scheduled for September.

With the schedule mapped years in advance, Carnival is positioning 2026 dockings to combine routine maintenance and brand-led refurbishments with corporate-backed efficiency work, including hull and thruster-grid improvements, expanded air lubrication installations, and additional waste-heat and service-power upgrades identified through ship-specific modeling.

Frequently Asked Questions (FAQs)

How many drydock days does Carnival Corporation expect in 2026?

Carnival Corporation CFO David Bernstein said the company’s eight brands are expected to total more than 600 drydock days during 2026.

What are air lubrication systems (ALS) and how do they work?

Air lubrication systems create a layer of air bubbles between a ship’s hull and the water to reduce friction (drag). Carnival says the improved hydrodynamic performance can reduce fuel consumption, and Chris Millman said the company expanded the program after about two years of operational data from initial installations.

What is the AIDA Evolution program, and which ships are scheduled in 2026?

The AIDA Evolution program is an upgrade initiative tied to longer shipyard periods for AIDA Cruises vessels. In 2026, AIDAbella is scheduled to enter drydock starting in January and AIDAmar is slated for a November transformation, with both listed as nearly 50-day dockings.

How is Carnival using waste heat recovery systems?

Chris Millman said Carnival is increasing its focus on waste heat utilization, including an absorption chiller that uses waste heat to produce chilled water. He said the company recently completed its first retrofit of the absorption chiller system on a Carnival Cruise Line ship, after previously using the technology on a newbuild.

How does Carnival plan and test efficiency upgrades before drydock?

Millman said Carnival uses digital twins, virtual replicas of ships, to evaluate potential modifications before committing to shipyard work. He said drydock planning is typically mapped five years in advance, with larger efforts planned two to three years out and smaller items often organized about a year ahead.